3D metrology test, or three-dimensional surface measurement, is a key test for controlling the performance of fiber optic connectors. In the production and functioning of fiber optic cable components, 3D interferometer, as the instrument to perform optical interferometry, plays an important role to enable vendors to inspect the fiber endface and control strictly the endface dimension. The three main properties measured are the radius of curvature, apex offset, and fiber height.

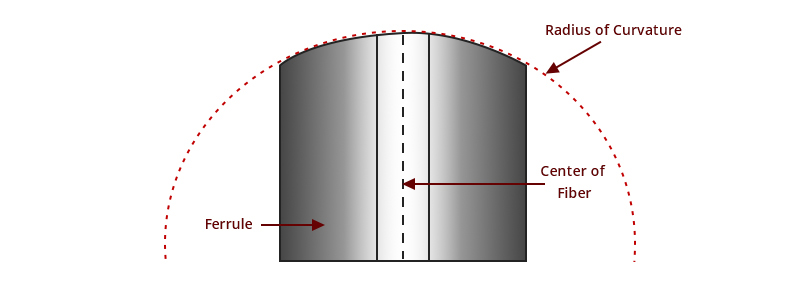

Radius of Curvature

As you can see in the image below, radius of curvature is the roundness of the ferrule’s endface. The radius of curvature of high-quality fiber patch cable connector endface should be controlled in a certain range. Too tight of a radius will put too much compression on the glass and too loose will put too much on the surrounding ferrule with not enough glass compression. Too much or too little radius can cause light scatter or inadequate physical contact for optimal signal transfer. Only a proper radius will allow for right compression and maximum performance.

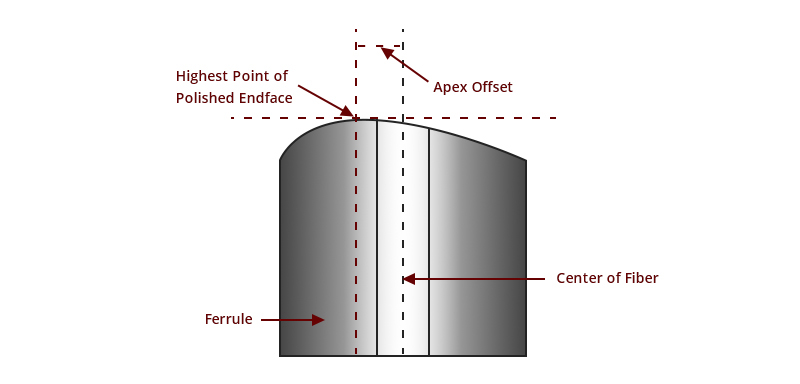

Apex Offset

Apex offset refers to the linear distance between the highest point of polished ferrule endface and the center of fiber. It is a key term to amplify during polishing process. Incorrect polishing can be the reason for apex offset.

In theory, mated connectors with centered apex offsets should have perfect core-to-core connection, without any air gap. If there is a large apex offset, an air gap can be created, resulting in high IL and RL. Optical connectors with PC or UPC ferrules should set the apex offset at 0 degrees vertical angle during polishing. When ferrule is perfectly perpendicular to the polishing surface, the apex will be the exact center of fiber. APC ferrule is another case. The ferrule should be at an angle of 8 degrees to the fiber, instead of perfectly vertical.

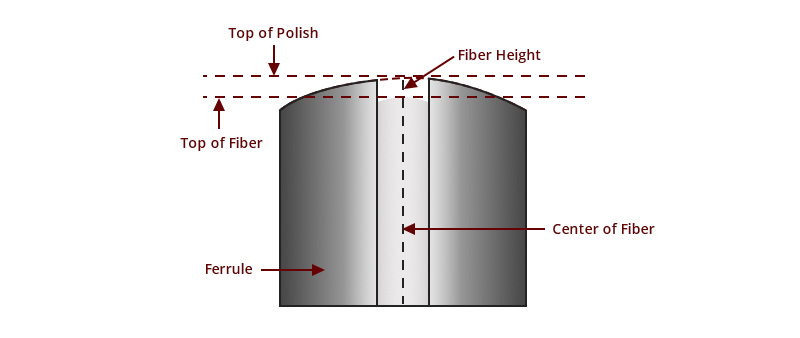

Fiber Height

Fiber height is the height that a fiber core extends from the ferrule surface. The fiber height should be not too high or too low. If too high, the fiber may bear the risk of being damaged when mated; if too low, gap will occur between the mated connector, resulting in increased insertion loss. Especially for those transmissions with stringent insertion loss requirements, gaps are certainly something you should avoid.

Standard 3D interferometer values are different in fiber modes and polish styles, thus the specific products should meet or exceed relevant industry-accepted endface geometry standards. The following chart is the endface geometry requirements of MTP single mode trunk cable connector based on IEC/PAS 61755-3-31 and IEC/PAS 61755-3-32.

汉信

汉信