Everything has two sides. Similarly, slim patch cords cannot be guaranteed that there are no disadvantages. The disadvantages of slim patch cable are manifested in higher DC resistance and higher insertion loss, which cause to limit the using distance.

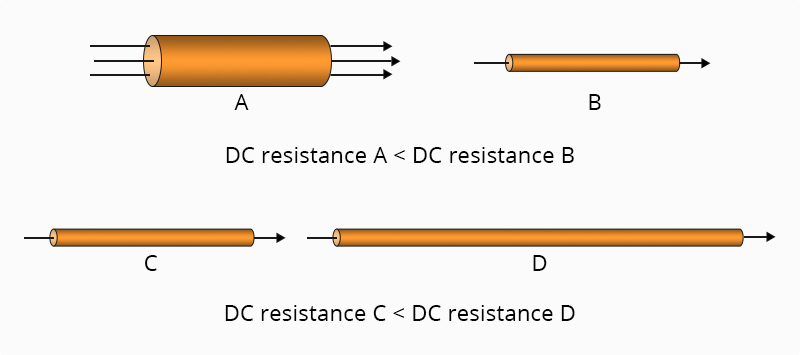

The DC resistance of a conductor is a measure of the conductor’s ability to resist current flow. The DC resistance increases as the length of conductor increases proportionally. Additionally, it is affected by the diameter of the conductor——the DC resistance of a larger size is smaller than that of a smaller size. Therefore, the slender jumper essentially has a greater resistance.

According to the IEEE standard, the DC link resistance of a pair of channels should be 25 ohms (Ω) or less. The new TIA 568.2-D standard recommends a 28 AWG patch cable in the channel keep the length within 15 meters to lower DC resistance within 25 Ω.

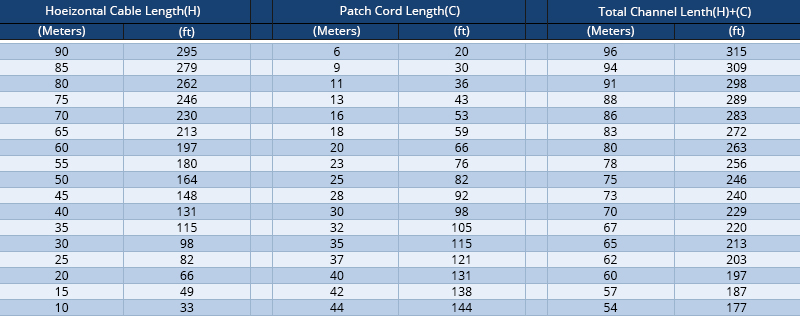

From a signal point of view, insertion loss is considered a more important performance parameter. Like DC resistance, it is affected by the size and total length of the conductor. Generally, a cable with a smaller wire diameter has more insertion loss than a cable with a larger wire diameter. Since the loss is directly related to the length of the channel, the use of slim patch cords needs to reduce the total length of the channel. For example, the 28 AWG patch cord has a derating factor of 95%, which means that it’s 95% more loosy than a horizontal cable of the same length. In the case of a 90m permanent link, the longest possible channel is 96m (see the table below to combine the longest possible 28 AWG patch cord length with various permanent link lengths).

However, most users are not worried about derating. Because these thin wires are mainly deployed in the high-density wiring area of data centers, where the link length is often much less than 90 meters.

In addition to the disadvantages of the slim patch cable mentioned above, it is more important to pay attention to the safety and reliability of the slim patch cable. To take the FS slim patch cable as an example, the slim patch cable is made with pure copper conductors, so its performance and security are enhanced over other cables made of copper clad aluminum. The slim patch cable certified by UL Listed and RoHS complies with safety and performance requirements, which makes it a more consistent and reliable connection when hard wiring your devices.

汉信

汉信