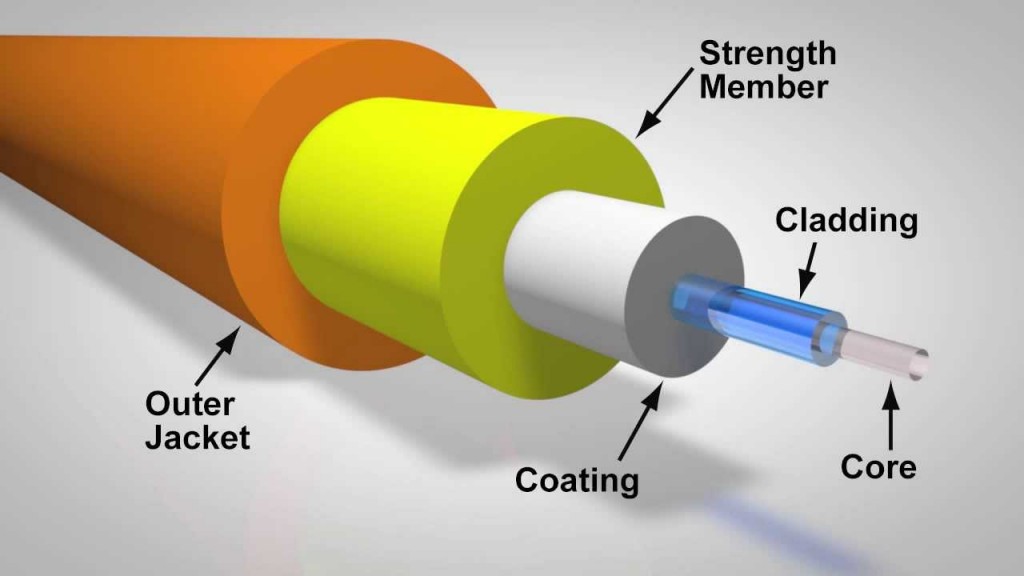

Fiber cable jacket is made of various types of materials. It’s important to consider the jacket type when selecting the compatibility with the application’s connectors and environment. The table below contains some of the most common fiber cable jacket material types used both indoor and outdoor cables:

| Jacket Material | Benefit of Jacket Material |

|---|---|

| PE (Polyethylene) | PE has excellent properties of moisture and weather resistance, and has the good electrical properties over a wide temperature range. It’s also abrasion resistant. So PE is the standard jacket material for outdoor fiber optic cables. |

| PVC (Polyvinyl Chloride ) | PVC is usually low-cost, flexible, fairly rugged, and a flame/oil-resistant material, so it can be formulated to function in a variety of environments and applications. In other words, it can be used as the jacket materials for both indoor and outdoor cables. |

| PVDF (Polyvinyl Difluoride) | PVDF is used for plenum cables, because it has better fire-retardant properties than PE and produces little smoke. |

| LSZH (Low Smoke Zero Halogen) | LSZH jacket is free of halogenated materials which can be transformed into toxic and corrosive matte during combustion. LSZH materials are used to make a special cable called LSZH cable, which is a good choice for inner installations. But it is the most expensive jacket material. |

汉信

汉信