Product Description

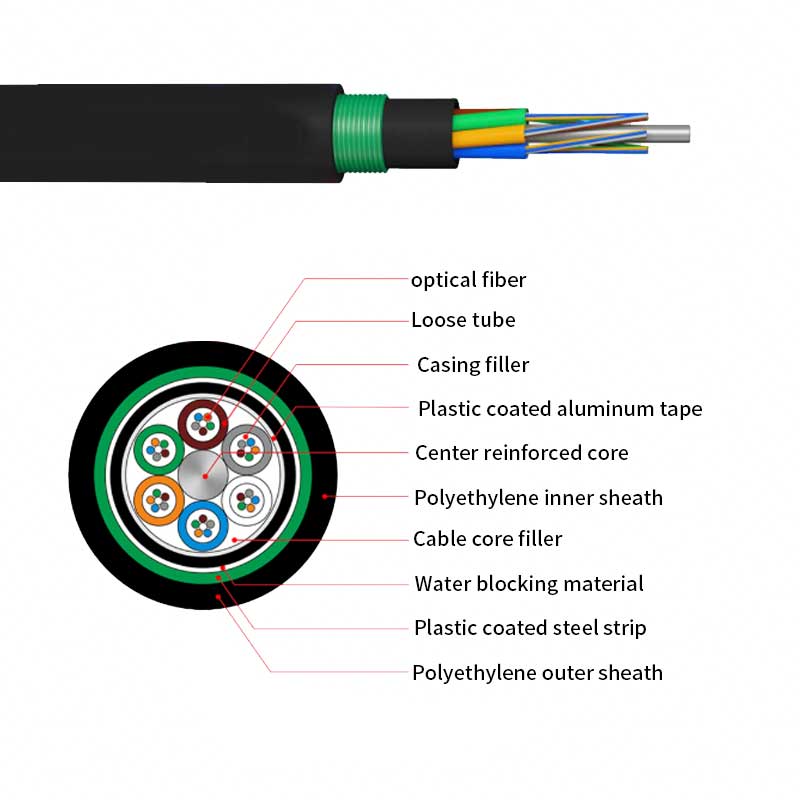

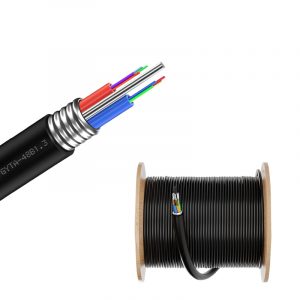

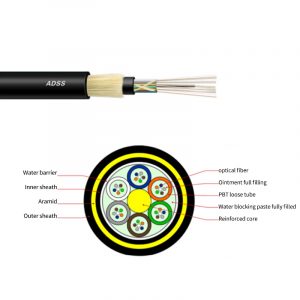

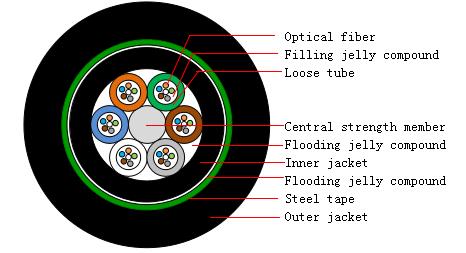

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. Then the cable core is covered with a thin PE inner sheath. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

Characteristics

· Good mechanical and temperature performance

· High strength loose tube that is hydrolysis resistant

· Special tube filling compound ensure a critical protection of fiber

· Crush resistance and flexibility

· PE/LSZH sheath protects cable from ultraviolet radiation

· 100% cable core filling

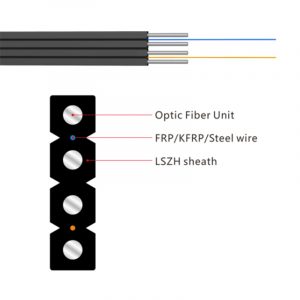

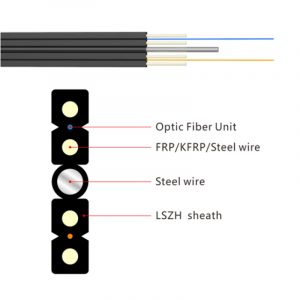

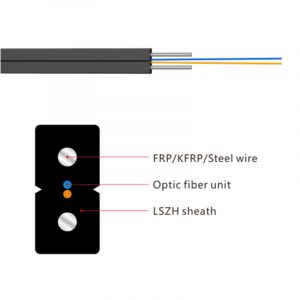

Product Structure

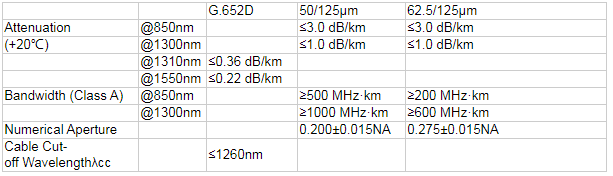

Optical Characteristics

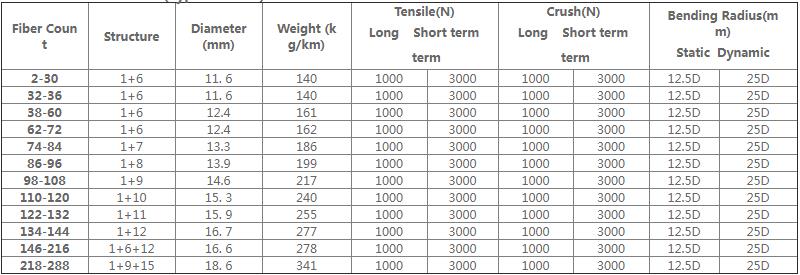

Technical Parameters

汉信

汉信