Product Description

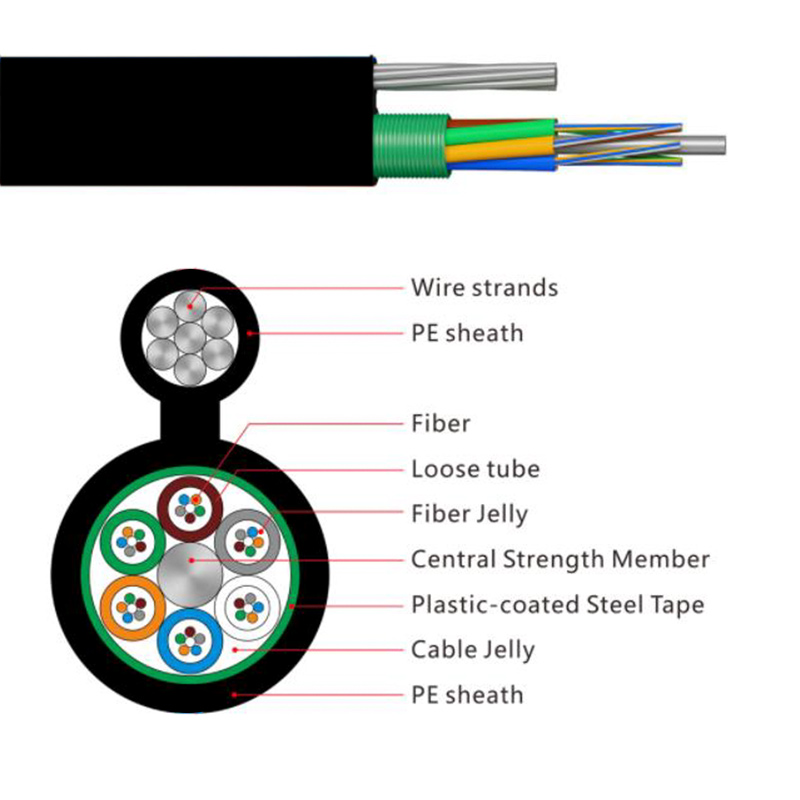

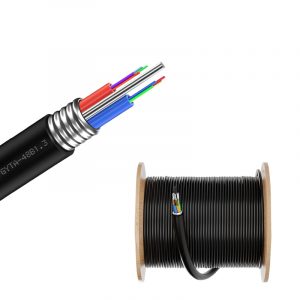

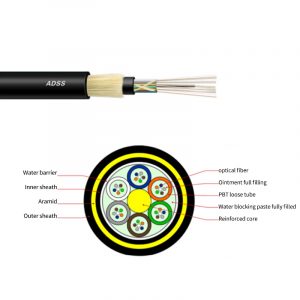

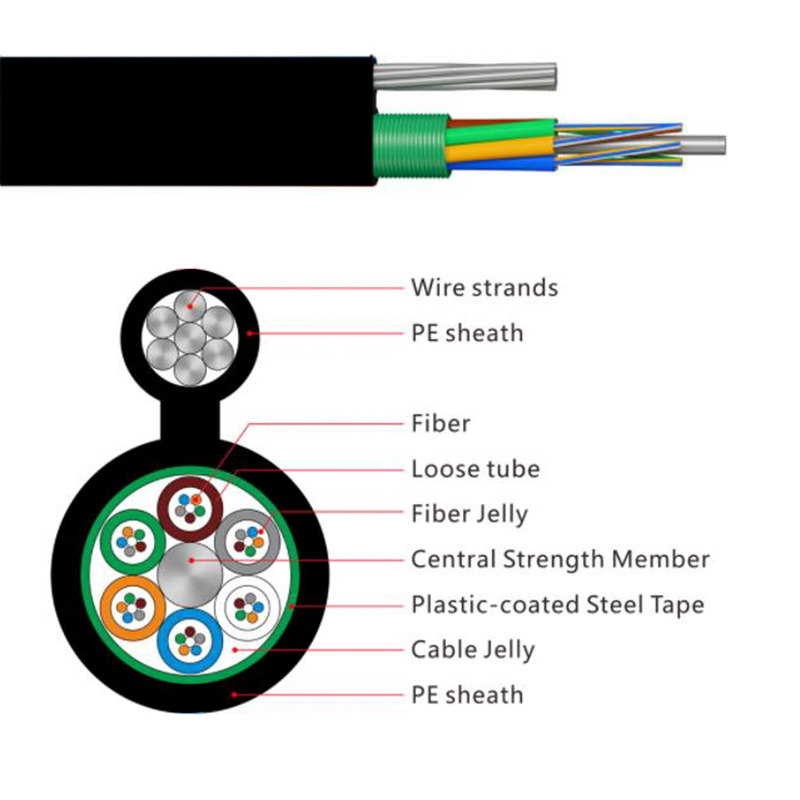

The fibers, 250μm , are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire locates in the center of core as a metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular cable core. After an Aluminum Polyethylene Laminate (APL) moisture barrier is applied around the cable core, this part of cable accompanied with the stranded wires as the supporting part are completed with a polyethylene (PE) sheath to be figure 8 structure.

Product Structure

Product Features

·High tensile strength of stranded wires meet the requirement of self-supporting and reduce the installation cost.

·Good mechanical and temperature performance

·High strength loose tube that is hydrolysis resistant

·Special tube filling compound ensure a critical protection of fiber

·The following measures are taken to ensure the cable watertight:

·Loose tube filling compound

·100% cable core filling

·APL moisture barrier

Product Standard

·GYTC8A cable complies with Standard YD/T 1155-2011 as well as IEC 60794-1.

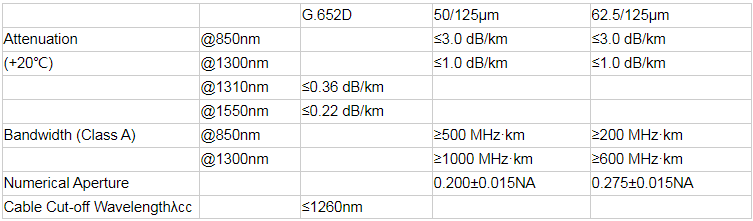

Optical Characteristics

Technical Parameters

| Cable Type | Fiber Count | Cable Diameter mm | Cable Weight Kg/km | Supporting Wire Spec | Connection Diameter mm | Tensile Strength N | Crush Resistance N/100m | Bending Radius mm |

| GYTC8A-2~60 | 2~60 | 9.5×18.3 | 218 | ф1.0mm×7 steel strand | High * width 3.0×2.5 | 4000/7500 | 500/1000 | 15D/30D |

| GYTC8A-62~72 | 62~72 | 10.5×19.3 | 240 | ф1.0mm×7 steel strand | High * width 3.0×2.5 | 4000/7500 | 500/1000 | 15D/30D |

| GYTC8A-74~96 | 62~72 | 12.5×20.3 | 280 | ф1.0mm×7 steel strand | High * width 3.0×2.5 | 4000/7500 | 500/1000 | 15D/30D |

| GYTC8A-98~120 | 62~72 | 13.5×21.3 | 320 | ф1.0mm×7 steel strand | High * width 3.0×2.5 | 4000/7500 | 500/1000 | 15D/30D |

| GYTC8A-122~144 | 62~72 | 15.0×24.3 | 350 | ф1.0mm×7 steel strand | High * width 3.0×2.5 | 4000/7500 | 500/1000 | 15D/30D |

汉信

汉信