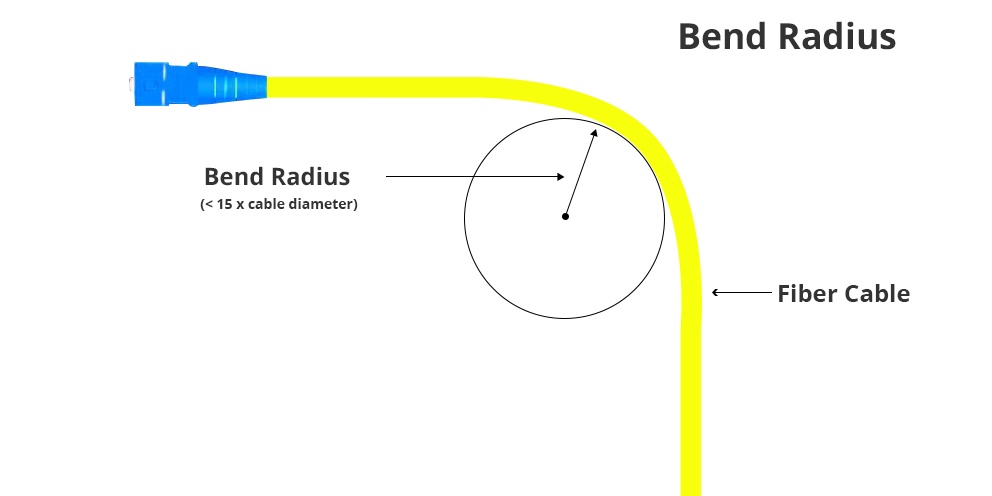

Bend radius is the amount of bending that can occur before a cable may sustain damage or increased attenuation and limit bandwidth performance. When a fiber cable is bent excessively, the optical signal within the cable may refract and escape through the fiber cladding. Bending can also permanently damage the fiber by causing micro cracks. The result is known as bend loss: a loss of signal strength that may compromise the integrity of the data transmission.

Note: Excessive pulling tension and overly tight fasteners can also cause transmission problems and micro-bends in optical fiber cables.

The minimum bend radius is the smallest allowable radius for a given fiber optic cable to be bent around. The new standard ANSI/TIA/EIA-568B.3 sets performance specifications, minimum bend radius standards and maximum pulling tensions for 50/125-micron and 62.5/125-micron fiber optic cables. For inside plant cable, the fiber cable bend radius is 10 times the cable’s outside diameter under no pull load, and 15 times the cable’s outside diameter when subject to tensile load.

How to Calculate Bend Radius of Fiber Optic Cable?

In generally, the allowable bend radius varies based on cable type, outside diameter (OD), and the condition of the cable under stress both during installation (tensile load) and after installation when the cable is reset (no-load). The following formula is used to calculate bend radius:

Minimum Bend Radius = Cable Outer Diameter x Cable Multiplier

The cable multiplier is determined by industry standards and cable type. For fiber optic cables, the cable multiplier is six times for cables rated 5000 volts or less, eight times for cables rated over 5000 volts.

汉信

汉信